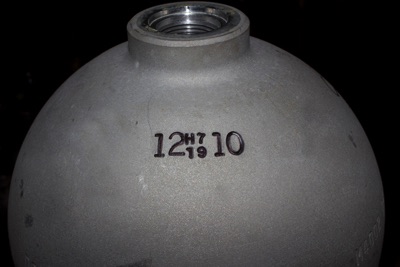

During a Hydrostatic Test a cylinder is filled with water (hence the Hydro part of its name) and then pressurized to its appropriate test pressure. For 3AA steel cylinders and 3AL aluminum cylinders this is 5/3 of its working pressure, about 5000 psi for aluminum scuba cylinders and 3750 psi for most steel low pressure scuba cylinders. The pressure is held for a minimum of 30 seconds (the Static part of the test) and the amount the cylinder expands is measured. Like balloons cylinders expand when they are filled, a typical aluminum 80 scuba cylinder will expand about 55cc when it is filled to its working pressure, and like a balloon the cylinder is a little bit bigger when the pressure is released. For most cylinders they must return to within 10% of their total expansion. If a cylinder passes the hydrostatic test and a visual inspection it gets stamped with the date of the test. For most cylinders the Hydrostatic test is good for five years.

If the cylinder fails either the Hydrostatic test or the visual inspection the DOT markings are Xed out and the cylinder is condemned and should not be used.

A cylinder that is less than two feet in length and less than two inches in diameter does not need a Hydrostatic Test.

A cylinder that does not have a current Hydrostatic test may not be filled.